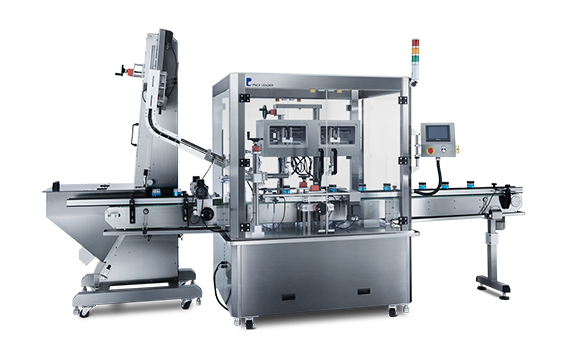

Model Number:CCP-132

Model No.:

- CCP-132 Continuous Style Pick & Place Capping Machine (Servo System)

The Pack Leader CCP-132 is an innovative, fully automatic capper which benefits a wide variety of companies requiring capping capabilities. The machine’s triple servo driven system controls the capping function to ensure that the caps are the proper tightness so the product meets perfection when it is presented to the market.

- Features

- Specifications

Simple to Use

- The CCP-132 innovative and highly efficient design enables easy operation and quick change-over for different capping specifications and requirements. Especially its new continuous style pick & placing function which drives by triple servo motors can exactly make sure all the caps can be capped precisely and tightly on the products.

Built to Last

- In strict compliance with Good Manufacturing Practices (GMP) standards, the CCP-132’s solid steady frame is made from durable 304 stainless steel and anodized aluminum. This durability translates into an easy-to-maintain machine with a long, durable life.

Flexible

- The CCP-132 capper offers exceptional flexibility, and adapts to a wide range of bottle and cap sizes.

- The sturdy conveyor system has adjustable conveyor guide rails to accommodate the varying product sizes.

- The smart PLC system controls all the digital parameters via HMI which make operating flexibly and easily.

Efficient

- The CCP-132 design allows for low energy consumption to protect the environment and save energy while still producing a generous output to keep up with production needs.

- The capper’s integrated touch-screen controls bring ease of use to the operator, while increasing efficiency and productivity for each project.

- The machine’s Bottle Jam Detection feature stops the machine automatically and notified the operator in the case of a bottle jam.

- The precise, cap feeding chute ensure smooth cap feeding to avoid cap jamming.

- The Production Preset function enables the CCP-132 to automatically stop once the preset quantity of products has been capped.

- The Monitor setting provides data records to help track maintenance and usage.

- The CCP-132’s battery-free microprocessor control system can maintain up to 30 default settings and job memory even after machine sits idle for a period of time.

- The CCP-132 features a management setting with password protection, which allows management to have more capabilities, while restriction access to those directly involved with the project at hand.

- The capper level deck can be adjusted up and down to accommodate products with various height demands.

- The capper has adjustable electronic torque values that help eliminate damage to caps and reduce insert wear.

- The CCP-132 is equipped with motor overload protection to avoid improper operation causing motor damage.

- The machine is fully enclosed and well-suited for simple and quick changeovers, with built-in mobility castors that enable easy movement from one production area to the next.

- Manufactured under strict ISO 9001 quality control procedures, the CCP-132 has a protective acrylic shield that is compliant with safety standards. The machine is built from durable stainless steel and anodized aluminum to protect against harsher environments and to withstand heavy usage from three shift operations.

- The machine is controlled by the Servo System, which is based on an advanced brushless motor system that provides fast, accurate output.

| Supply Voltage | 220/380 VAC, 50/60 Hz, 1 Phase |

|---|---|

| Power Consumption | 1.5KW |

| Air Pressure | 4~6kg |

| Dimension | (L) 3200mm x (W) 1400 x (H) 2160mm |

| Net Weight | 870kg |